Details

Dinghua Intelligent Material Counting Machine DHKC-S500

Dinghua X-Ray Non destructive Testing Instrument DH-X7

Dinghua X-Ray Non destructive Testing Instrument DH-X8

Dinghua X-Ray Non destructive Testing Instrument 3D/CT Plane Direct Scanning DH-X9

Dinghua Online X-Ray Non destructive Testing Instrument DHKC-1300

.jpg)

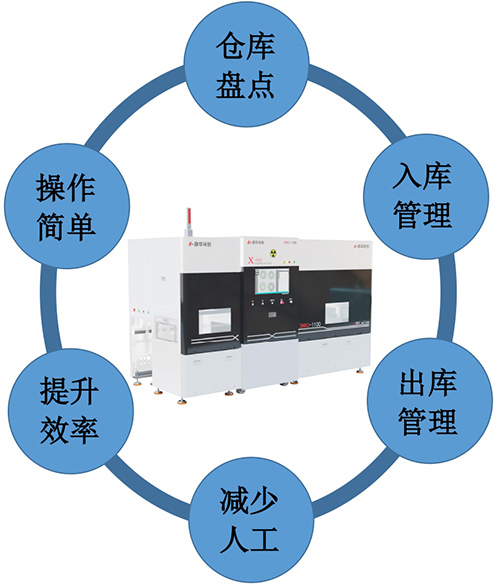

2、 Introduction to Intelligent Material Counting Machine

1. Material counting speed: 12-15 seconds/disc counting accuracy: up to 99.99%;

2. Product sorting, automatically removing NG products;

3. Automatic label printing, automatic labeling, and label review inspection:

4. Self developed AI intelligent material counting algorithm software;

5. Reduce inventory time, eliminate unnecessary manpower, and assist other personnel in collecting or changing lines to shorten downtime during line changes;

6. The smart material counting machine adopts digital data, which can print barcode stickers or directly upload them to the database. However, traditional counting instruments require one for each operator, which takes up a lot of space. The counting results are still manually filled in, which may result in errors or omissions;

7. Smart material counting machines can significantly improve the situation of material shortage, loss, leakage, and shortage, digitize material storage management, reduce material inventory costs, and improve material inventory accuracy;

8. Can dock with AGV carts, automatically load and unload materials, without the need for manual processing;

9. Integrate with MES/ERP/WMS and other system data, exchange real-time data, and upload and update material information in a timely manner.

3、 Application Fields

4、 Technical parameters and specifications

| X-ray tube parameters | |

| Tube type | Reflective sealed micro focal point emitter |

| Tube voltage range | 30-80KV (optional) |

| Tube current range | 200-700μA |

| Maximum output power | 56W |

| Micro focus size | 139um |

| Flat panel detector parameters | |

| Tablet type | Amorphous silicon flat panel detector |

| Pixel matrix | 3072x3072 |

| Field of View | 427x427mm |

| resolution | 3.6Lp/mm |

| Image frame rate (1x1) | 1fps |

| AD conversion bits | 16bits |

| Equipment performance parameters | |

| Tray size | 7-15 Tape Reel |

| Tray height | 6-80mm/60-80mm (manual feeding) |

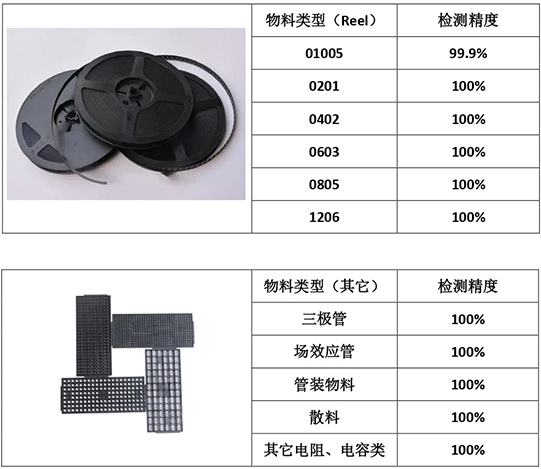

| Minimum Device | 01005 |

| system integration | MES/ERP/WMS, etc |

| input power | 220V10A 50-60HZ |

| control system | Industrial computer WIN10 64 bit |

| Overall dimensions | 830 X 1400 X 1950m |

| Net weight of equipment | About 2200KG |

| interface system | Integrate with MES/ERP/WMS and other system data, exchange real-time data, and upload and update material information in a timely manner |

| software | Support SPC statistics in any format, automatic saving of images and results |

| Counting accuracy | 01005 can reach 99.98%, 0201 and above 99.99% |

| barcode scanning | Built in camera, automatic one-dimensional and two-dimensional barcode scanner |

| Counting time | Approximately 12 seconds per set |

| Testing items and dimensions | |

| Maximum size of tray | 17 inches |

| Minimum size of material tray | 7 inches/containing smaller bulk materials |

| Maximum thickness of the tray | 80mm |

| Minimum thickness of material tray | 3mm |

| Compatible with the smallest device type | 1005 |

| Tray coverage rate | Continuously updating the database to cover 99.98% of materials on the market |

| Counting time | Approximately 12 seconds per set |

| Cutting method | Automatically put into the material cart or automatically flow into the material frame |

| Abnormal material storage area | Abnormal materials during post test fall into the material box (automatically inserted by the robotic arm) |

| Labeling method | CCD vision recognizes the coordinates of the old barcode on the tray, and the robotic arm attaches the new barcode to the tray and covers the old barcode |