Details

Dinghua Intelligent Material Counting Machine DHKC-S500

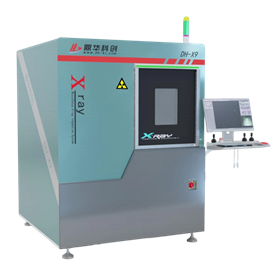

Dinghua X-Ray Non destructive Testing Instrument DH-X7

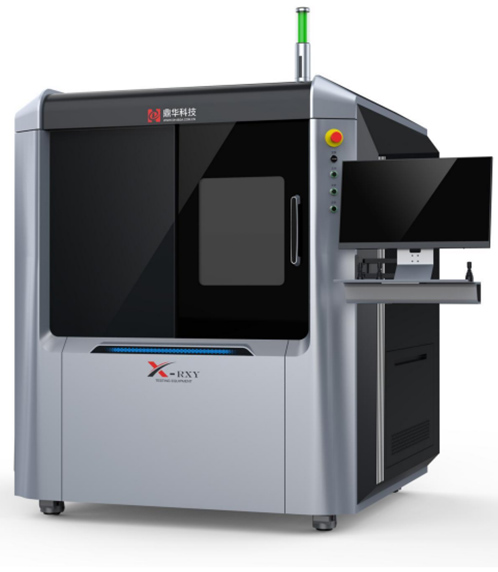

Dinghua X-Ray Non destructive Testing Instrument 3D/CT Plane Direct Scanning DH-X9

Dinghua Online X-Ray Non destructive Testing Instrument DHKC-1300

Dinghua Intelligent Material Counting Machine DHKC-1100

.jpg)

1、 Product images

2、 Product advantages and features

The X-ray source adopts a closed X-ray tube with long service life, maintenance free, and 130KV;

The new generation of high-definition digital flat panel detectors, with high-resolution design, can obtain the best images in a very short time;

Laser automatic navigation and positioning, quickly select the shooting location;

X/Y/Z axis motion control, easy to operate;

CNC detection mode, for fast and automatic detection of multi-point arrays;

Tiltable angle: plus or minus 60 degrees, tilt multi angle detection makes it easier to detect sample defects;

Optional 360 degree rotation function;

The visualized high-definition navigation window is easy to operate and can quickly locate the detection target location;

550mm * 550mm stage;

Easy and fast operation, quickly identify target defects, and receive two-hour training to get started;

3、 Application Fields

Mainly used in semiconductors SMT、DIP、 Electronic component testing, covering various packaging types such as IC, BGA, CSP, flip chip POP, Void, HIP, Insufficient, etc. It can also be used for automotive parts, aluminum die-casting modules LED、 Testing for special industries such as batteries, photovoltaics, molded plastics, and ceramic products.

4、 Technical parameters and specifications

| X-ray source | Light tube type | Closed reflection target microfocus X-ray source |

| Light tube voltage | 40-130KV (optional) | |

| Light tube current | 10-300uA | |

| Maximum output power | 39W | |

| Micro focus size | 5μm | |

| Flat Panel Detector | Detector type | Amorphous silicon flat panel detector |

| Maximum pixel matrix | 1536x1536 | |

| Field of View | 130.56x130.56mm | |

| spatial resolution | ≥5.5Lp/mm | |

| pixel pitch | 85μm | |

| stage | platform dimensions | 550mmx550mm |

| Testing Scope | 500mmx500mm | |

| stage | 10kg | |

| chassis | Inner lead plate | 5mm thick lead plate (isolating radiation) |

| size | 1450mm(L) x1530mm(W) x2000mm(H) | |

| weight | About 1500kg | |

| Other parameters | power supply | AC220±10% 10A |

| temperature and humidity | 22±3°C 50%RH±10%RH | |

| Whole machine efficiency | 1500W | |

| Safety Specifications | Radiation dose | Adopting a steel lead steel protective structure, the observation window is made of leaded glass, and the measured radiation dose equivalent rate is ≤ 1 μ SV/H, which meets international standards |

| safety interlock | Three high-sensitivity limit switches are installed at the front and rear door positions of the equipment. Once the door is opened, the X-ray source will automatically protect it, and the light tube will not start. | |

| Electromagnetic safety door | The observation window is equipped with an electromagnetic switch. When the X-ray tube is in operation, the observation window cannot be opened | |

| Emergency stop button | In case of emergency, press to immediately power off. |

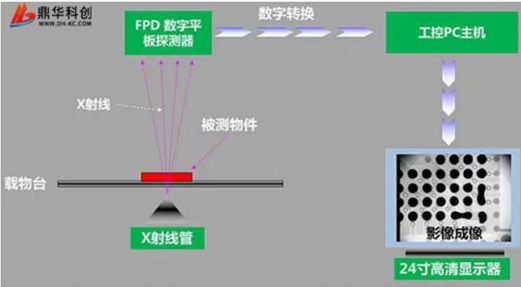

5、 Equipment working principle diagram

6、 Software functions

| functional module | Operation method | Joystick keyboard and mouse complete all operations (drag the mouse to move the motion axis, slide the wheel to zoom in or out of the light pipe Z-axis) |

| X-ray tube control | Click the mouse button to turn on or off X-rays, display real-time tube voltage and current values, click the up and down buttons or drag the slider to manually input adjustments; Real time display of tube power and micro focus size. | |

| status bar | By flashing red and green, it indicates the interlock status, preheating status, and X-ray switch status. | |

| Image effect adjustment | The filtering level, brightness, contrast, and filter of the image can be freely adjusted to achieve satisfactory image effects. | |

| Navigation window | After taking platform photos with a high-definition color camera, click on any position in the photo to quickly find the detection target location | |

| Motion axis status | Display real-time coordinates and magnification. | |

| Test results | Display each measurement result in order (bubble ratio, distance, area, and other measurement items) | |

| speed control | By using the spacebar and software, the movement speed of each axis can be adjusted to slow, constant, and fast. | |

| Bubble rate measurement | automatic calculation | It can measure bubbles in packaging components such as BGA and QFN, and automatically calculate the proportion of BGA bubbles in the selected area. Can set threshold values, automatically determine void rate, and maximum void rate |

| adjust parameters | By adjusting parameters such as threshold, size, blob type, and calculation, accurate results can be obtained through automatic computation. | |

| Size calculation | Calculation of the proportion of tin filled holes | It is commonly used to measure the solder pass rate of through-hole components, and the proportion and height of the component's solder climbing surface can be obtained by selecting a rectangular box. |

| Quick ranging | Obtain the distance between two points through any frame. | |

| distance between a point and a line | Obtain the distance between points and lines through arbitrary points and lines. | |

| angle | Set points A and B as reference lines, then click point C to measure the angle between the BA and BC rays. | |

| rotundity | Commonly used for measuring circular components such as solder balls, selecting any circular component to obtain a circle, and measuring the circumference, area, and radius. | |

| Horizontal rectangle | Commonly used for measuring square components, selecting a square frame to determine its length, width, and area | |

| Auto Detection | CNC inspection | For multiple detection points, simply set any position and measurement item, and the software will automatically capture each detection point and save the image. |

| laser positioning | Red dot laser positioning device, dual assistance, easy navigation |

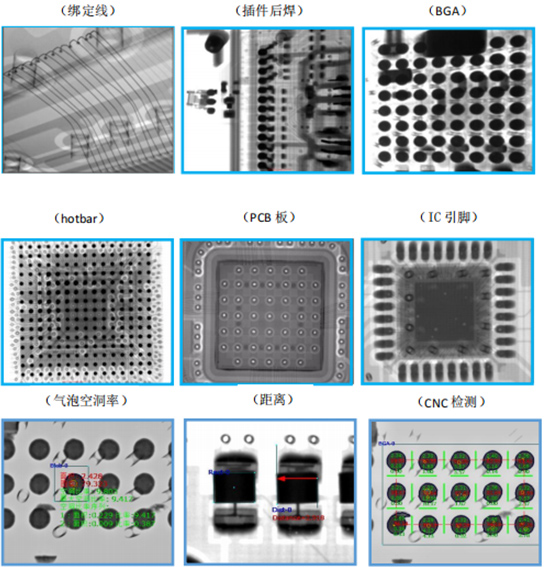

7、 Example image