Details

Dinghua X-Ray Non destructive Testing Instrument DH-X7

Dinghua X-Ray Non destructive Testing Instrument DH-X8

Dinghua X-Ray Non destructive Testing Instrument 3D/CT Plane Direct Scanning DH-X9

Dinghua Online X-Ray Non destructive Testing Instrument DHKC-1300

Dinghua Intelligent Material Counting Machine DHKC-1100

.jpg)

1、 Product images

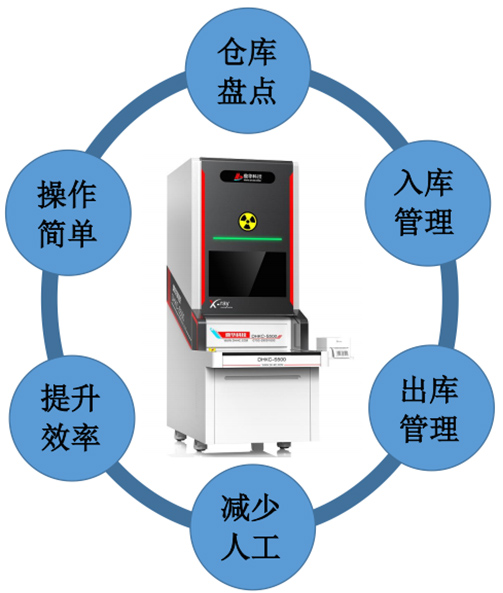

2、 Introduction to Intelligent Material Counting Machine

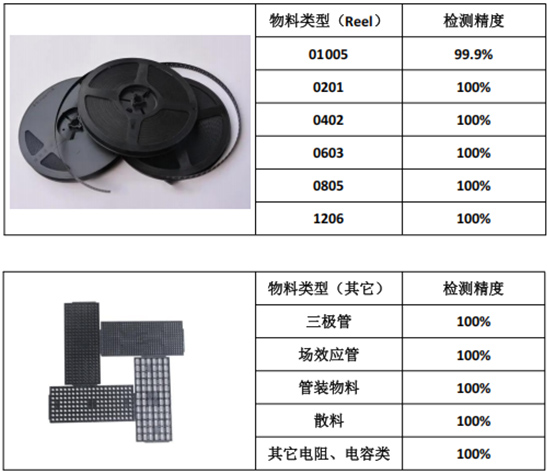

The X-RAY material counting machine is used for rapid counting of roll and reel materials used in SMT industry production, with intelligent modular design and assembly based on Industry 4.0 standards.

It can be equipped with artificial intelligence deep learning software and cloud based update system for all product items such as 7-17 inch Tape Re 1/Tra/IC.

By using X-ray imaging technology, production materials are inspected and image information is obtained. Through image algorithms for rapid counting, the actual quantity of materials is obtained. At the same time, the number of materials can be classified and counted by category, and the data information can be integrated with the MES system.

3、 Application Fields

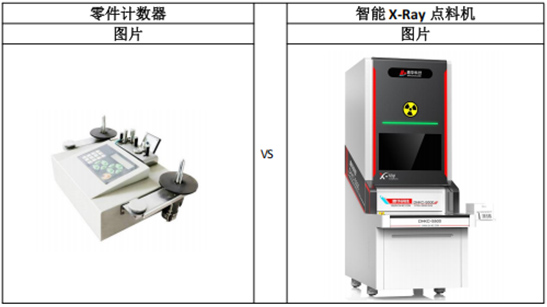

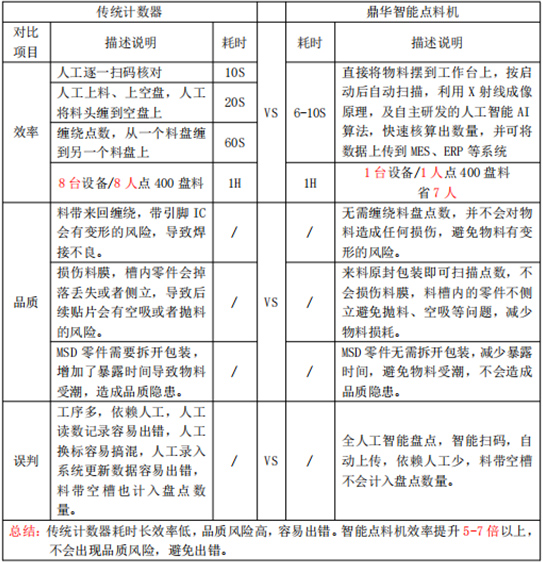

4、 Comparison between Traditional Counter and Intelligent Material Counting Machine

5、 Equipment functions

1. Compared to traditional counters, intelligent material counting machines do not require unpacking or transferring material trays.

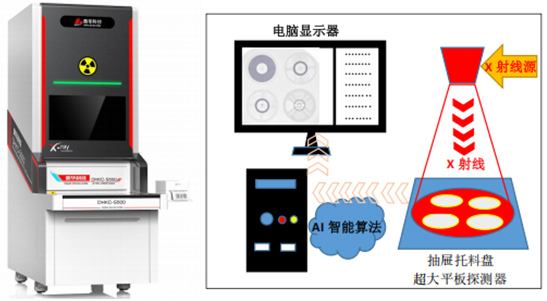

2. Adopting a side window type enclosed tube X-ray source, it has a long lifespan and is maintenance free.

3. The flat panel detector adopts a 17 inch ultra clear screen, with clear imaging and no deformation.

4. The diameter of the measurable tray is 7-17 inches (with 4 7-inch trays or 1 17 inch tray placed at the same time).

5. Accelerated the counting speed and reduced labor costs.

6. Drawer style automatic entry and exit, grating automatic sensing, preventing hand pinching and convenient access.

7. Equipped with artificial intelligence (AI) algorithms and an innovative detection environment.

8. Integrate with MES/ERP/WMS and other system data, exchange real-time data, and upload and update material information in a timely manner.

9. Full sensing recognition of material labels, error prevention and mixing prevention, real-time integration with printers.

10. Designed with reference to human sitting posture, it is less prone to fatigue, occupies less space, and is easy to move around.

11. Suitable for various types of surface mount components, SMD devices above 01005.

6、 Schematic diagram of the material counting machine

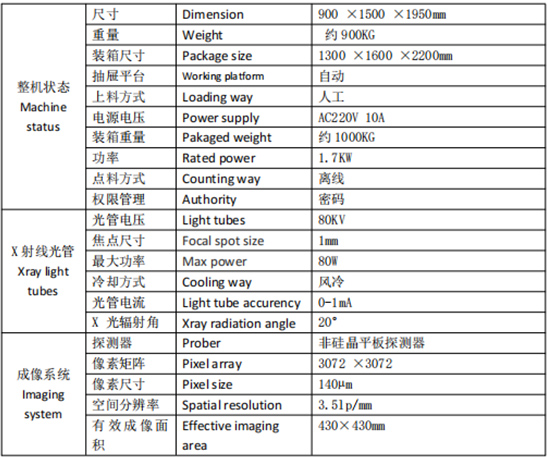

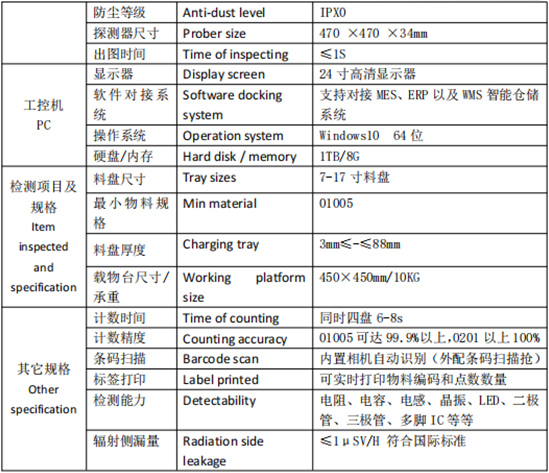

7、 Technical parameters and specifications

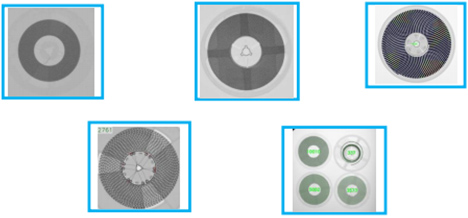

8、 Detecting images