Details

.jpg)

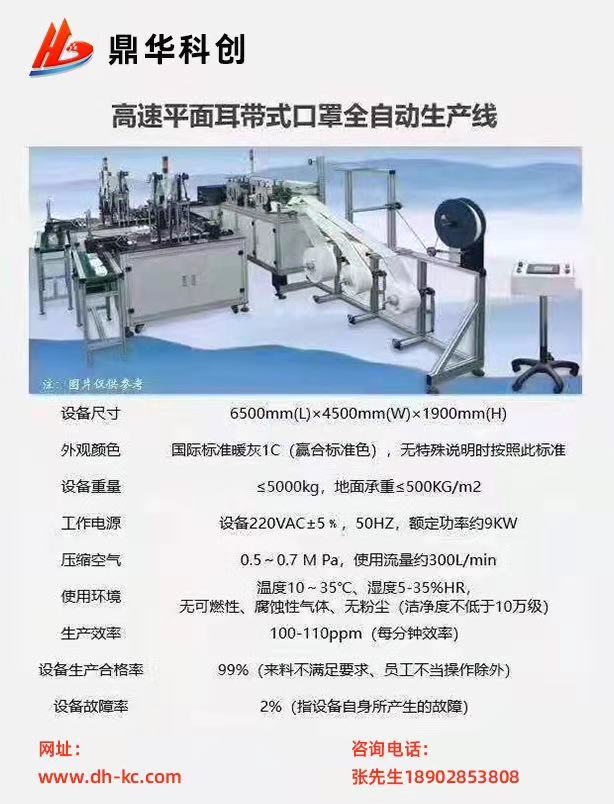

1、 Equipment Introduction:

This production line achieves fully automated production of flat masks, mainly including roll feeding, folding and pressing, and nose pressing

The processes of beam reinforcement feeding, mask forming, mask cutting, ear strap feeding and welding, and finished product cutting are completed

The entire production process from raw materials to finished masks.

The produced mouth is comfortable to wear, without pressure, and the mask has good filtering effect, which fits the shape of the face and can be suitable for people

Used in industries such as healthcare, electronics, mining, and construction.

2、 Equipment characteristics:

1. Variable frequency drive with stepless speed regulation,One time welding molding, wear-resistant, equipped with a power amplifier inside the chassis;

2. Integrated production,Only one person is needed to operate,Variable frequency adjustment;

3. High speed production,Nissan masks8More than 10000 pieces;

4. Produce a variety of different products,Changing molds can produce products of different shapes and specifications;

3、 Basic parameters:

Connection part machine size: 3300(L)*2700(W)*1160(H)MM

Machine size for one to two machines: 3950(L)*3650(W)*1800(H)MM

Equipment weight:≤5000kgGround bearing capacity≤500KG/m2

working power supply:equipment220VAC±5%, 50HZThe rated power is approximately9KW

compressed air:0.5~07MPaUsing traffic approximately300L/min

Usage environment:temperature10~35CHumidity5-35%HR,

No flammable, corrosive gases, no dust(Cleanliness not less than10ten thousand level)

production efficiency:80-110ppm(Efficiency per minute)

Equipment production is qualifiedrate:99%(Unsatisfactory incoming materialsfootExcluding requirements and improper operations by employees)

setBackup failure rate:2%(Refers to the malfunction caused by the device itself)

electricity press: AC220V, 50HZ,60HZ,1P

produce quantity: 70-80piece/minute

consume electricity: 8.5KW