Details

.jpg)

Shenzhen Dinghua Technology Development Co., LtdWith a strong R&D and production team, we have been committed to the research and production of automated screw machines for many years

We have solved a series of product locking screw problems for numerous companies and enterprises, and have 38 patents and 92 quality control processes. We have completed the research and production of a single station automatic screw machine to a fully automatic dual station screw machine. We have now produced an automatic screw machine for Xiaomi TV speakers, which has been applied in the locking screw process of various product lines, saving manpower and a lot of costs for the company. Now Dinghua is promoting this mature product nationwide. We welcome all enterprises to visit Dinghua for guidance and help you solve the problem of locking screws for your products.

DinghuaAutomatic screw locking machineTechnical advantages:

Imported screw feeder from Japan, with high feeding efficiency and low failure rate;

Original Japanese HIOS torque electric screwdriver, with accurate and adjustable torque, stable performance, and precise locking;

Equipped with an intelligent feedback system for screw tightening, it will sound an alarm in case of loose screws, slipping teeth, or missing locks;

Standard universal fixture suitable for screw locking of multiple models;

Automatically start the attached product, providing greater stability during the screw locking process;

Forward and backward functions are more suitable for assembly line operations;

The elastic protection structure can protect the product from being crushed in abnormal situations;

The motion control adopts artificial intelligence touch screen operation, which is more automated and simple;

Teach programming methods, simple and reliable, and easy to get started quickly.

Dinghua Technology specializes in producing automatic screw locking machines, suction type dual platform automatic screw locking machines, and specializes in designing automatic screw locking for electronic products such as mobile phones, tablets, GPS, LED, etc. Adopting Japanese imported HIOS electric screwdrivers and feeders, imported motors, Panasonic PLC control, precise and stable locking of screws, capable of achieving one screw per 1.0 second.

The mechanical arm platform of this screw machine is constructed with die cast aluminum profiles, which have a beautiful appearance and a solid structure. All machined parts are processed using CNC precision carving to ensure the precision and consistency of the parts, with 100% strict machine calibration standards to ensure the accuracy of the machine.

Machine features:

This adsorption type machine is suitable for the vast majority of screws and workpieces, and the machine automatically completes product locking according to the set coordinate position. When replacing the product, simply debug the universal fixture and select the corresponding program, the operation is very simple.

The feeding host adopts a wheel feeding method to sort the screws onto the vibration guide rail and transport them to the screw distribution system for distribution. The screws are adsorbed onto the nozzle through the suction component, and the robot automatically completes the locking according to the set coordinates.

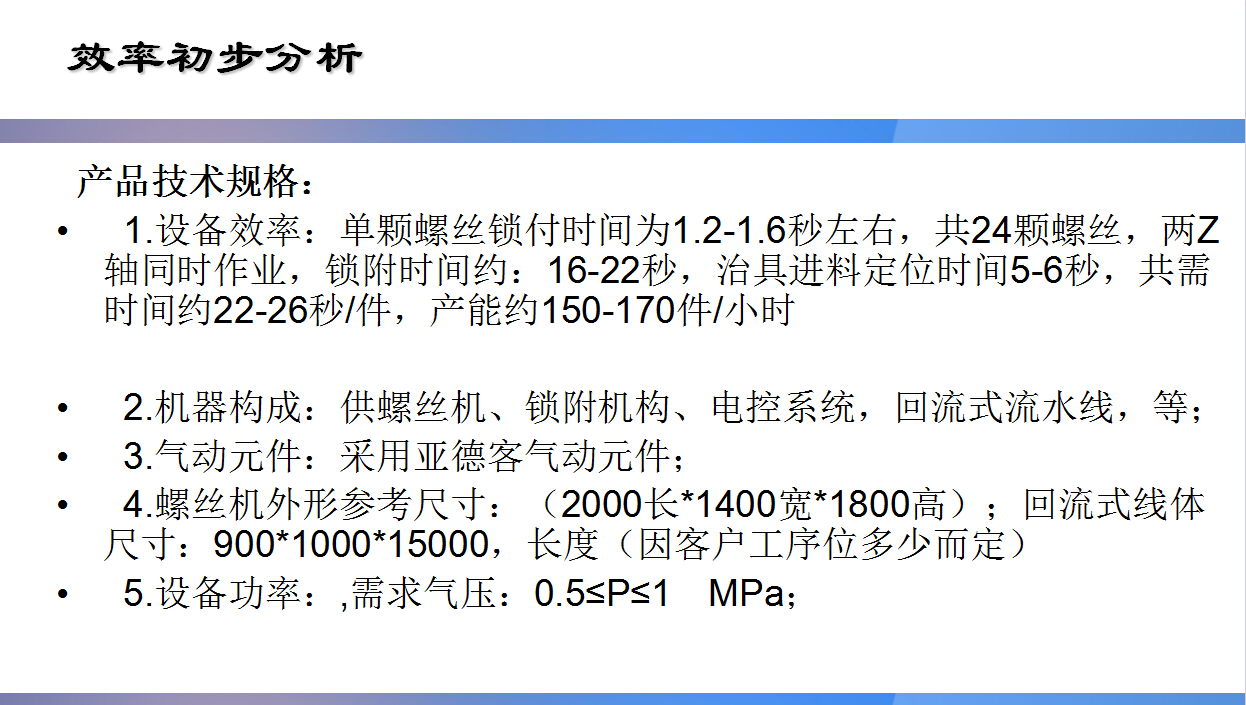

Specification parameters: